by Stephen Colley

Share

by Stephen Colley

Share

If you’ve recently purchased a Speedy 360 or 400 laser machine, you’re likely eager to get started. Unboxing and setting up your new equipment is an exciting process, and we’re here to guide you through each step. This comprehensive guide will ensure a smooth, safe, and efficient setup of your new laser machine.

If you’ve recently purchased a Speedy 360 or 400 laser machine, you’re likely eager to get started. Unboxing and setting up your new equipment is an exciting process, and we’re here to guide you through each step. This comprehensive guide will ensure a smooth, safe, and efficient setup of your new laser machine.

Delivery and Inspection

Your Speedy 360 or 400 laser machine arrives via freight, carefully packed in a wood-reinforced box on a wooden pallet. This robust packaging is designed to protect your investment during transit. Upon delivery, we recommend inspecting the package for any significant shipping damages. Minor scuffs are normal, but anything more substantial should be noted.

Simplified Unboxing Instructions

For those who prefer written guidance, each side of the box features a QR code. Scanning this code provides you with simplified written unboxing instructions, a perfect complement to this video guide. To begin, you’ll need either a pair of scissors or a utility knife.

The Unboxing Process

Follow these steps to safely unbox your laser machine:

- Cut the Banding Straps: Start by cutting the two straps securing the box.

- Release the Box Sides: Locate the four white twist clips on the box’s long sides. Rotate these clips clockwise to release the sides.

- Remove the Box Top and Sides: Carefully cut any tape holding the box top to the sides. Lift off the top and set aside the sides.

- Take Off Extra Supports: Remove any additional supports and the wooden top frame.

- Cut Away the Plastic: Use scissors or a utility knife to cut the plastic, particularly around the machine’s base.

Machine Removal from the Pallet

Underneath the machine, you’ll find ramps for easy removal. Create a lever with these ramps to lift the machine and remove the blocks underneath. This step might require assistance.

Securing the Ramps (Optional)

For solo unloading, secure the ramps with screws to ensure they stay in place. This extra measure is recommended for safety during the offloading process.

Unloading the Laser Machine

Unlock the wheels at the front of the machine. Ensure a clear path for offloading and carefully guide the machine down the ramps. We advise having assistance during this process for optimal safety.

Final Setup Steps

Once the machine is offloaded, remove all protective materials. Open the machine to find an accessory box containing essential items such as a lens cleaning kit, quick reference guidebook, ethernet cable, metric hex keys, and more.

Calibration and Readiness

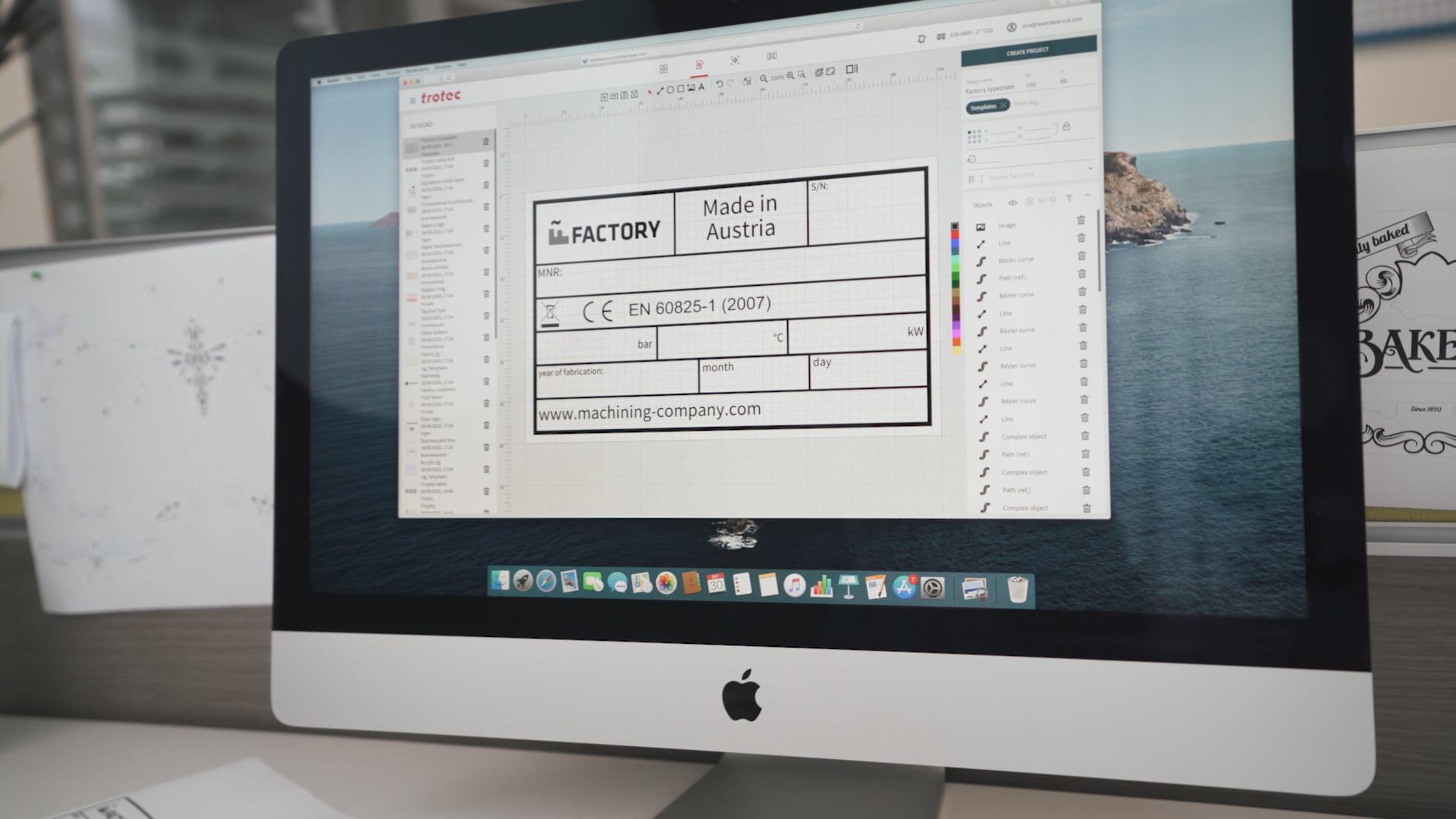

Inside the machine is a sheet of Trolase plastic for calibrating the overhead camera. This step is crucial for the optimal operation of your laser machine. With calibration complete, your Speedy 360 or 400 is ready for installation and use.

Your Feedback is Valuable

We’re here to support you every step of the way. If you have questions or need further assistance, please reach out through the comment

STAY IN THE LOOP

Subscribe to our free newsletter.

Introducing Tech Store: Your Premier Destination for Laser Accessories Click Here To Visit The Store! Elevating Your Laser Experience Greetings to our valued customers and laser enthusiasts! We are excited to unveil a significant enhancement to our customer services – the launch of Tech Store! At Trotec Laser, we continually strive to improve your experience […]

Exploring the Latest Features and Improvements in Ruby® 2.7: A Comprehensive Guide Ruby® laser software has always been a frontrunner in providing innovative solutions to enhance laser processing efficiency. The latest update, Version 2.7, is no exception. It brings an array of new functions and improvements that are set to revolutionize how users interact with […]

What to Expect with the Launch of Trotec Ruby’s 2.6 Update Trotec Laser GmbH has recently launched the highly anticipated Ruby® 2.6 update on June 6, 2023. This update brings a range of exciting features and improvements to the Trotec Ruby software, enhancing the user experience and expanding the capabilities of Trotec laser machines. Here’s […]