by Stephen Colley

Share

by Stephen Colley

Share

Exploring the Latest Features and Improvements in Ruby® 2.7: A Comprehensive Guide

Ruby® laser software has always been a frontrunner in providing innovative solutions to enhance laser processing efficiency. The latest update, Version 2.7, is no exception. It brings an array of new functions and improvements that are set to revolutionize how users interact with their laser machines. Let’s dive into the key features of this update:

New Functions

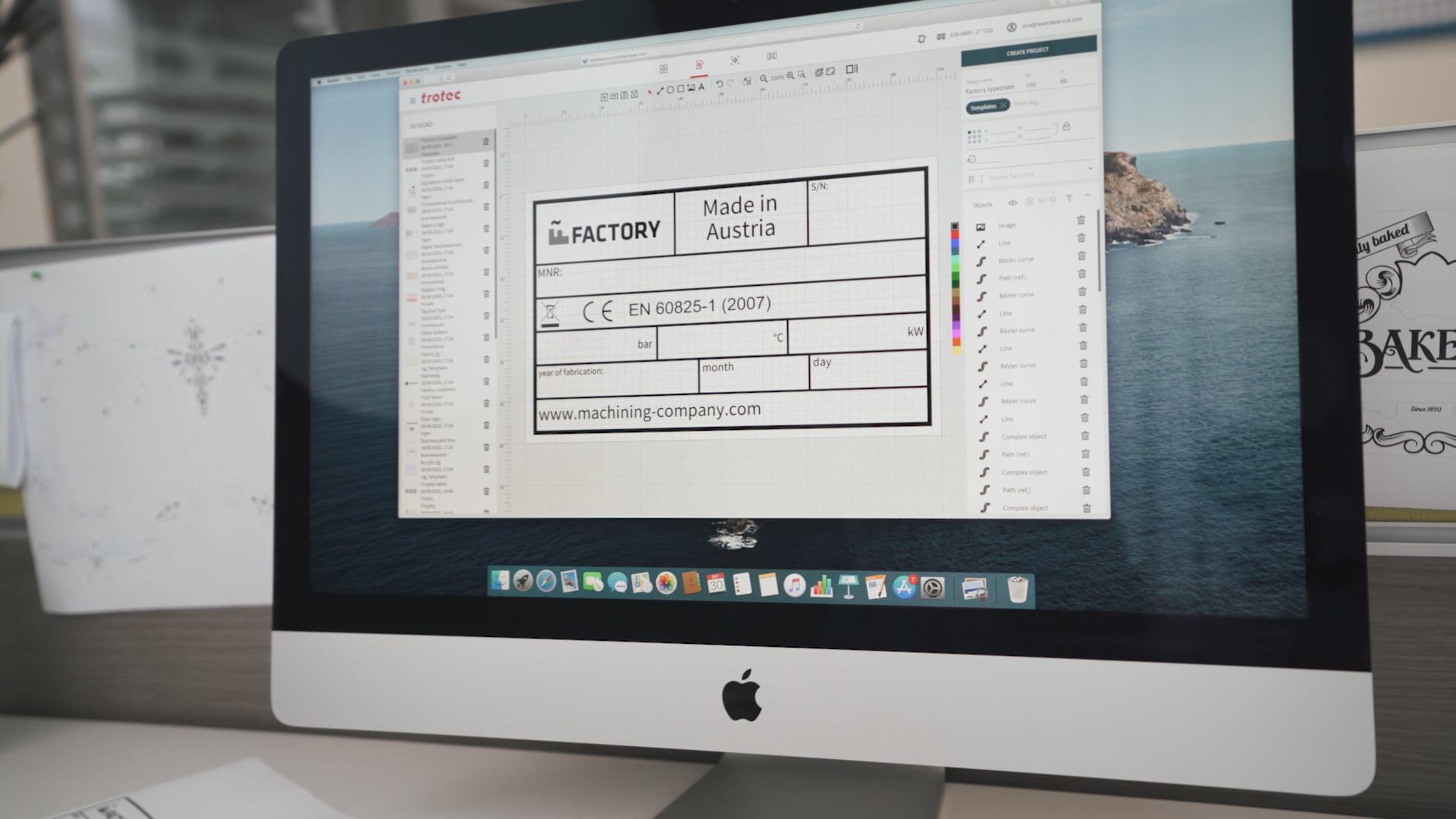

Processing Dynamic Data – The most exciting feature in this update is the ability to import data directly from CSV files into laser jobs. This function is especially beneficial for producing customized items like nameplates, type labels, or promotional materials. The ease of importing data streamlines the process, making it a valuable tool for businesses. To get a better understanding of this function, don’t miss the video tutorial in the Ruby® help center.

*Note: Remember, this is a Beta function in release 2.7, so activate it in the settings.*

Move Laser Head to Exact Coordinates – Precision is key in laser processing, and the new update doesn’t disappoint. In the Prepare screen, users can now input X and Y coordinates to move the laser head to specific locations. This feature is crucial for accurate positioning and setting up markers. However, it’s important to note that this is only available for machines not using the Run on Ruby® systems.

Recognition of the Lens Used – Another notable addition is the lens detection feature on the touch display of Run on Ruby® machines. When initiated, the laser head moves to a reading position to identify the lens in use, which is then displayed and can be confirmed in the Ruby® Settings. This feature simplifies lens exchange and negates the need to use a computer for this process.

*Compatibility: Available for Speedy 400 and Speedy 360 with Vision Design & Position camera and a current lens holder with a Trotec QR code.*

*Note: Changing the lens, either on the touch display or in settings, will delete jobs in the queue.*

Improvements and Updates

Changes in the Settings Menu – The Settings menu has been reorganized into categories for easier navigation. Additionally, users can now directly set the X and Y offset without requiring a Trotec service technician.

R/Q Series Fully Supported – With release 2.7, the R and Q series lasers are fully supported, marking the end of their beta phase. This update ensures better integration and performance for these series.

Signed Installer – The new signed installer for Ruby® simplifies the download and installation process. It is no longer flagged as “unknown”, reducing the steps needed for manual updates.

Notable Bugfixes and Known Issues

Bugfixes – An issue with the round engraving device on R400 and Q400 has been resolved. Users should update the firmware to version 11.04.11.01.

Known Issues – Machines without an electronic Z-axis (R500, Q500) may encounter an error message related to the Z-offset. Setting the Z offset in the material to 0 and restarting the job can resolve this.

Ruby® 2.7 is a significant leap forward, offering features that enhance usability and efficiency. Whether it’s the convenience of processing dynamic data, precise movement of the laser head, or the new lens recognition functionality, these updates are tailored to meet the evolving needs of users. The thoughtful categorization of the settings menu and the support for R/Q Series lasers indicate a commitment to user-friendliness and versatility.

Moreover, the introduction of a signed installer is a small but impactful change, streamlining the installation process and enhancing user confidence in the software’s reliability.

However, it’s important to be aware of the existing limitations and bugs, such as the issue with machines lacking an electronic Z-axis. Understanding and adapting to these quirks will ensure a smoother experience with Ruby® 2.7.

In summary, Ruby® 2.7 is not just an update; it’s a significant upgrade that empowers users with more control, precision, and ease of use. It’s a testament to Ruby®’s dedication to continuous improvement and customer satisfaction. As users explore these new features and improvements, they can look forward to a more efficient, streamlined, and productive laser processing experience.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]STAY IN THE LOOP

Subscribe to our free newsletter.

Introducing Tech Store: Your Premier Destination for Laser Accessories Click Here To Visit The Store! Elevating Your Laser Experience Greetings to our valued customers and laser enthusiasts! We are excited to unveil a significant enhancement to our customer services – the launch of Tech Store! At Trotec Laser, we continually strive to improve your experience […]

If you’ve recently purchased a Speedy 360 or 400 laser machine, you’re likely eager to get started. Unboxing and setting up your new equipment is an exciting process, and we’re here to guide you through each step. This comprehensive guide will ensure a smooth, safe, and efficient setup of your new laser machine.

What to Expect with the Launch of Trotec Ruby’s 2.6 Update Trotec Laser GmbH has recently launched the highly anticipated Ruby® 2.6 update on June 6, 2023. This update brings a range of exciting features and improvements to the Trotec Ruby software, enhancing the user experience and expanding the capabilities of Trotec laser machines. Here’s […]